How Integrating Empirical Data empowers Engineering Workflows

The term empirical originates from the Greek word empeiria (ἐμπειρία), which in English translates to experience, or knowledge gained through experience.

How Integrating Empirical Data with Design Automation Empowers Engineering Workflows

Empirical data in the Engineering context pertains to historical performance test data when a product is either tested in controlled conditions (laboratory or factory testing) or data recorded through real-world (field) testing. Traditionally, engineering teams relied heavily on referring back to empirical data for design validations. The advent of AI and Industry 4.0 digital transformation technologies like IOT and digital twins has made it much more commercially viable and practical to capture or monitor a product’s performance data in real-time for a large number of use-cases.

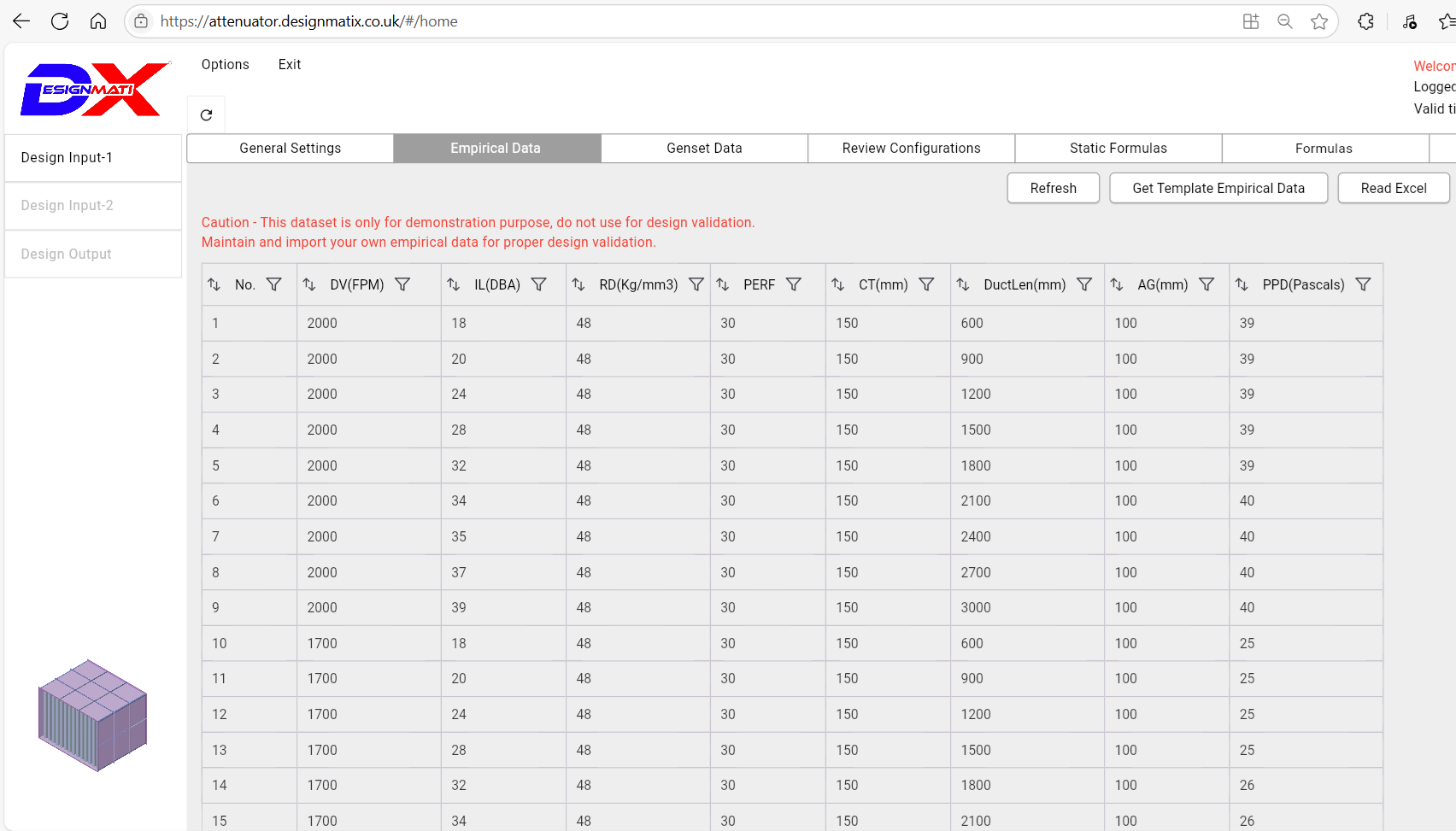

Since the empirical data becoming more and more readily accessible, Designmatix’s proprietary technology facilitates integrating customer’s legacy empirical data-set with their design automation applications that could drastically eliminate the friction between the two ends of Engineering value-addition cycle: One end being the definition of customer requirements as a starting point and the other end being the compliant design output- a CAD model. As a result, this empowers engineers in multiple transformative ways, bridging real-world performance with digital design. This synergy leads to faster iterations, smarter decisions, and better products. Here’s how:

-

Data-Driven Design Improvements

Design Engineer sets customer requirements in the Designmatix Application (DXApp)

Empirical data pertaining to the product’s field performance integrated into DXApp

DXApp’s design automation algorithms compare empirical data with customer requirements and select design output parameters in the form of ‘Equations’

Equations drive the default design configuration (CAD model) from ‘what should work’ to ‘what has proven to work’

Thus, DXApp eliminates the need for any calculations or manual iterations, reduces overengineering and unnecessary safety factors, saving the design engineer’s time as well as product cost significantly

Some typical examples:

A steel structure fails stress testing in the field-> Integrating failure data into DXApp allows for targeted reinforcement.

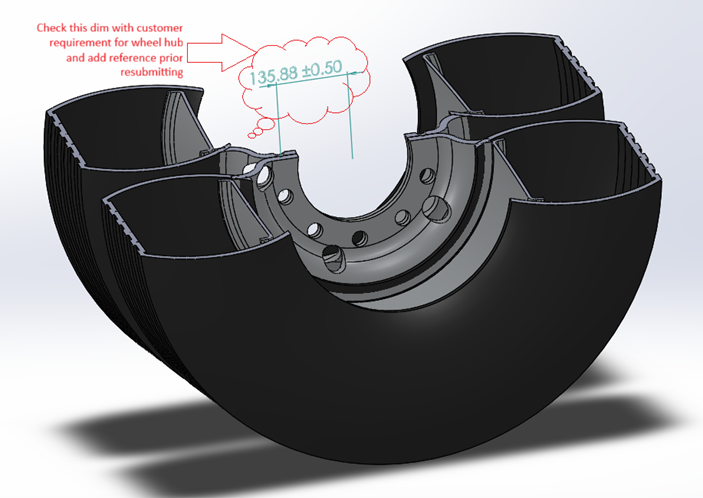

An Attenuator or Genset Canopy doesn’t perform as desired, causing equipment overheating or dissipating higher than specified noise levels. Integrating empirical data into DxApp allows for generating 100% compliant product design configurations instantly

-

Accelerated Iteration Cycles

With empirical data integrated into DxApp, Engineers avoid manual iteration loops with programmed loops, thus drastically improving speed.

CAD models can auto-adjust using parametric rules linked to performance data.

Result: Get the right design always & instantly allowing faster go-to-market.

-

Closed-Loop Feedback for Continuous Improvement

IoT sensors can capture product’s performance data in real-time and feed it back into CAD via a PLM (Product Lifecycle Management) or digital twins.

Engineers can visualize failure trends and fatigue cycles directly on the 3D model, thus enabling next-gen designs to continuously evolve with real-time data.

-

Regulatory Compliance Audits

Empirical Input on performance feedback supports certification and regulatory inspection by showing real-world performance alignment.

Examples: Wind load test curve for a steel structure, identifying stress points based on actual deflection of a digital twin allows for remote inspection of a site.

- Crash sensor outputs in automotive

- Fatigue monitoring in energy

- Concrete curing sensors in infrastructure

- Real-world engine load cycles in fleet vehicles

- Pressure transient logs in gas pipelines

- Strain gauges in offshore wind foundations

- IV-curve tracking in solar plants allows for efficiency curve monitoring,

- Vibration data in rotating machinery

- Thermal imaging in electronics

Validates design assumptions, ensures regulatory compliance, and strengthens audit trails across industries.

-

Automated Design Rules & Optimization

Engineers can define design constraints and optimization rules based on historical test data

Auto-generate geometry that meets fatigue thresholds or pressure tolerances.

Leverage AI-driven generative design tools using empirical data as fitness criteria.

Empirical data can replace or more accurately enhance or supersede theoretical formulas when designing products because it reflects how products actually performed in real-world conditions, not just how products were designed based on formulas and assumed conditions.

Advantages of Design Based on Empirical Data Vs Theoretical Formulas

-

Gaps Between Theory and the Real World

Theoretical formulas often assume an Ideal (near-perfect) environment and materials e.g., uniform loading or constant pressure, temperature, humidity, or altitude above sea level etc.

Empirical data reflects how an actual product behaved in real-world conditions, including misuse and non-linear behaviour of materials and the environment.

Example: In plastic component design, the theoretical formula might assume isotropic strength. But empirical tensile and fatigue testing reveals directional weaknesses due to mold flow, leading to more accurate safety margins and optimized geometry.

-

Overdesign (or Under-design)

Theoretical design often builds in large safety factors due to uncertainty or lack of practical knowledge.

Empirical data provides quantified performance, allowing for tighter tolerances and smarter material usage.

Example: Aircraft structures are designed with safety factors, but after years of flight data (strain, pressure, fatigue), engineers use empirical fatigue curves to shave weight safely without compromising integrity.

-

Improves Predictive Accuracy

Simulations use theoretical inputs (load, stress, thermal transfer), but real systems may behave differently. Empirical data calibrates or replaces simulation models & enables digital twins that mirror real-world responses.

Example: Fluid Simulation software predicting airflow in the Attenuator duct may assume steady-state flow, but empirical airflow test data reveals turbulence and reverse flow zones, leading to redesign for better efficiency.

-

Enables Machine Learning & AI-Driven Design

Theoretical formulas are limited by what we already know. Empirical data enables data-driven models that discover new patterns. AI systems trained on empirical performance data can predict failures, suggest designs, or generate alternatives without using formulas.

Example: In battery design, an AIML model trained on empirical charge & discharge cycles predicts battery lifespan better than an analytical degradation model, informing thermal design and cell layout.

-

Feeds Back From Field to CAD

Once a product is deployed, real-world data can flow back into the design process to update models, algorithms, and formulas.

Example: A tractor chassis experiences torsional stress in rocky terrain far higher than predicted by the software simulation model. Vibration sensor data is integrated into the CAD design to reinforce the affected joints, modify the load path & avoid future weld failures.

Conclusion:

Regardless of the industry and design platforms, integrating empirical data in to Design workflows improves design efficiency by avoiding manual trial loops, optimizing product designs & eliminating un-necessary safety margins. Engineering teams can meet their tough deadlines for time to market and stay ahead of the competition through the power of design automation driven by empirical data Built with Designmatix’s proprietary technology at its core, try Attenuator, one of our flagship Design Automation software products for HVAC or energy industry. Unlock your understanding through getting your hands on for free.

Q1. Can I benefit from empirical data as a design engineer regardless of industry or design platform?

Ans1: Yes, all design engineers have to design products to be used in real-world. Empirical data from field measurements or test results can significantly remove reliance on theoretical formulas & improve how design engineers refine their work. It introduces a feedback loop between design and performance, enabling faster and more reliable designs. Empirical data helps substitute estimates with actual values that known and proven to have worked. This allows engineers to use real operating conditions in simulations, reduce design uncertainty & minimize the need for oversized safety margins. Data from testing or usage validates whether the design behaves as expected

Q2. I am not only responsible for product design. As a company director, does empirical data offers benefits to quality, manufacturing as well?

Ans2: Integrating empirical data as a feedback loop into business processes, plays a vital role not just in implementing design automation. Manufacturing and Quality processes can be enhanced by enabling evidence-based decisions. It helps optimize manufacturing process by identifying variations, inefficiencies, or deviations from desired outcomes through real-time or historical measurements. For Quality control process, empirical data supports on-line inspection, defect tracking, and root cause analysis, ensuring that products meet defined standards. By analyzing trends and patterns, manufacturers can implement predictive maintenance & improve overall throughput, thus improving overall operational excellence.

Q3. We have a design department but nobody using empirical data. All designs are based on formulas. Where and how should they start

Ans3: To implement an empirical data approach, a design department should begin by asking quality to furnish historical test data of relevant product. If data is not available, then look for identifying and collecting data from sources such as prototype testing, field performance, manufacturing deviations, or maintenance feedback. This data should then be analyzed to determine which parameters effect design decisions. Collaboration with cross-functional team is essential to ensure that data being captured is relevant, repeatable and accessible. Once suitable data is identified, it should be integrated into Design Automation CAD and simulation tools to refine assumptions and enhance model accuracy. Over time, this approach shifts the design culture from relying solely on theory or assumptions to one that is data-informed, agile, and quality-driven.

Q4. How to work out ROI before investing in Design Automation

Ans4: You begin by assessing current cost on task to be automated, define automation scope with an estimate of time savings, calculate investment cost to apply the formula – ROI= (Annual Savings−Annual Costs/Initial Investment) × 100

Here’s a step-by-step approach to working out an ROI:

Assess Current Costs:

- Measure average time spent on repetitive design tasks.

- Track error rates and associated rework costs.

- Quantify costs of delays in time-to-market caused by manual processes.

Define Automation Scope:

- List tasks that will be automated (e.g., modeling, drawing, BOMs).

- Estimate the reduction in manual input.

- Identify software, plugins, or custom solutions needed.

Estimate Time and Cost Savings:

- Calculate hours saved per task × labor rate.

- Multiply by number of tasks/projects per year to get annual savings.

- Add savings from reduced errors and design rework.

Calculate Investment Costs:

- Software licenses and subscriptions.

- Custom development or implementation cost.

- Training, onboarding, and internal setup.

- Ongoing support and maintenance.

Apply the ROI Formula:

ROI= (Annual Savings−Annual Costs/Initial Investment) × 100

Determine Payback Period:

- Divide initial investment by net monthly or annual benefit to estimate how quickly you’ll recover costs.

Factor in Intangibles (Optional but Valuable):

- Faster delivery timelines.

- Better design consistency and quality.

- Improved team productivity and morale.

- Scalability for future growth.